About MotorCarbon

Transforming carbon into everyday

MotorCarbon is a materials development company focused on engineering new processes to convert slurry oil, a common petroleum by-product, into an advanced technology carbon material. The resulting product, Meso-C™ can be utilized as a precursor for high stiffness carbon fibers for aircraft and automobiles, extremely conductive carbon foams for cooling electronics, and revolutionary new 3D printing powders for temperature-stable lightweight parts.

MotorCarbon is bringing carbon into everyday life.

Building not burning

MotorCarbon’s objective is to create ways to leverage oil as a component of building products versus burning it as bunker fuel. Traditionally, refineries dispose of their slurry oil waste stream as dirty bunker fuel for ocean-going ships.

Starting 1 January 2020, the International Maritime Organization (IMO) will restrict sulfur content in bunker fuels to less than 0.5% m/m (mass by mass), down from previous regulations limiting it to 3.5% m/m. As a result, refineries will have to adjust or look for alternatives to selling slurry as fuel.

MotorCarbon has the solution.

Company history

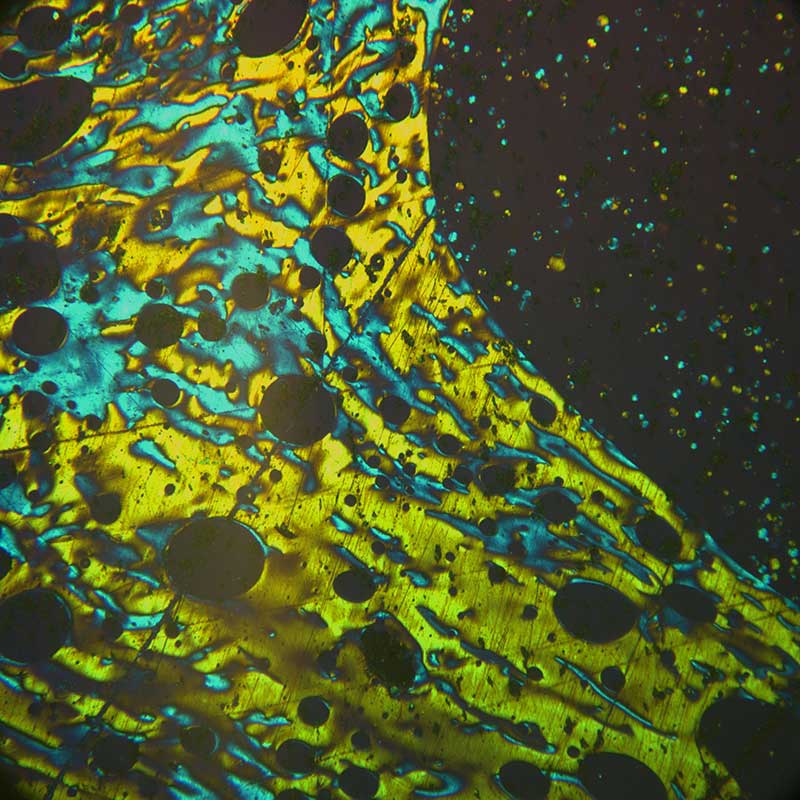

MotorCarbon was established in Dayton, OH in 1993 with the objective of developing low-cost carbon mesophase materials and a process to mass-produce pre-formed, near-net-shape engine parts made of pure carbon. The principles of MotorCarbon understand the technological aspect of distilling inexpensive slurry oil into petroleum pitch, from which high-value mesophase is derived. Their experience with experimental and mass volume petroleum products, material extraction techniques and carbon research is extensive. MotorCarbon has been awarded several research contracts with the Department of Defense and the Department of Energy as well as engine manufacturers. During the years of development work, it became apparent that, once small carbon parts can be mass-produced cost effectively, virtually every industry would use carbon as their choice material, with an unfathomable market potential.

MotorCarbon pitch process advantages

- Simple, low-cost manufacturing process for both petroleum-based isotropic pitch and mesophase carbon (anisotropic pitch).

- MotorCarbon’s differentiated process is marked by its high yield conversion from slurry oil to mesophase and non-batch, continuous methodology.

- Minimized ash and non-organic compounds in mesophase pitch. Higher purity mesophase carbon minimizes defects in pitch carbon fibers.

- IP Protection

- Patent-pending mesophase pitch process.

- Patent-pending additive manufacturing material and process.

- US Patent US6013371A – Carbon artifacts and compositions and processes for their manufacture